Introduction

PVC Masterbatch is a powerful additive that holds immense potential in revolutionizing the manufacturing and performance of PVC-based products. In this comprehensive guide, we will delve into the world of PVC masterbatch, exploring its benefits, formulation, and applications across diverse industries. Whether you’re a seasoned professional or a newcomer to the field, this guide will provide you with the essential knowledge to leverage the capabilities of PVC masterbatch effectively.

What is PVC Masterbatch?

PVC Masterbatch is a concentrated mixture of additives, pigments, and carriers, designed to enhance the properties of PVC materials. It is used during the processing stage to impart specific characteristics to the final PVC products. By incorporating PVC masterbatch into the manufacturing process, manufacturers can achieve improved color consistency, enhanced mechanical properties, UV resistance, flame retardancy, and more.

Benefits of PVC Masterbatch

- Improved Color Consistency: PVC masterbatch ensures uniform and consistent coloration throughout the product, reducing variations and enhancing aesthetics.

- Enhanced Mechanical Properties: By incorporating PVC masterbatch, products can exhibit improved strength, durability, and impact resistance.

- UV Resistance: PVC masterbatch provides excellent UV resistance, protecting the product from degradation and color fading caused by prolonged exposure to sunlight.

- Flame Retardancy: With the addition of flame retardant additives in PVC masterbatch, products can achieve enhanced fire safety properties.

- Chemical Resistance: PVC masterbatch can enhance the chemical resistance of PVC products, making them suitable for various applications.

- Weatherability: PVC masterbatch offers superior weather resistance, enabling products to withstand extreme temperatures, humidity, and outdoor environments.

Formulation of PVC Masterbatch

PVC masterbatch formulation involves careful selection and combination of additives, pigments, and carriers to achieve desired properties. Common additives used in PVC masterbatch include stabilizers, plasticizers, fillers, flame retardants, and processing aids. The formulation process requires expertise and thorough understanding of the target application, ensuring the masterbatch’s compatibility with the PVC resin and achieving the desired performance characteristics.

Applications of PVC Masterbatch

PVC masterbatch finds applications across a wide range of industries, including:

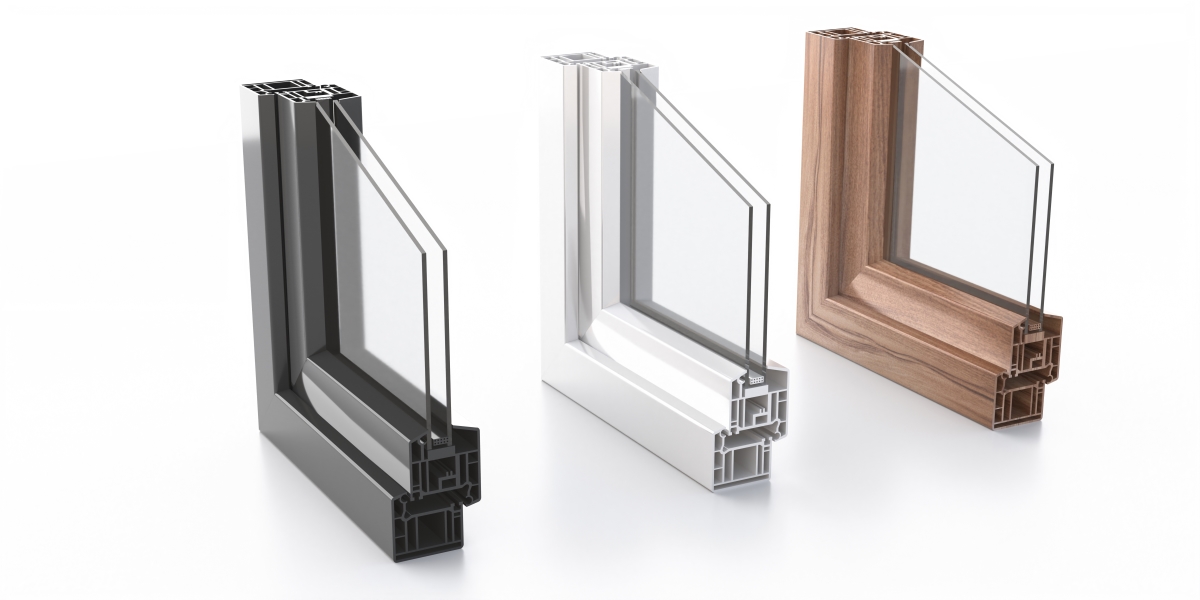

- Building and Construction: PVC masterbatch enhances the properties of PVC used in pipes, profiles, flooring, and other construction materials.

- Automotive: PVC masterbatch is utilized in automotive components such as interior trims, seals, and gaskets, providing color vibrancy and improved performance.

- Electrical and Electronics: PVC masterbatch is used in cable insulation, connectors, and electrical housings, providing electrical insulation and flame retardancy.

- Packaging: PVC masterbatch is employed in packaging films, bottles, and containers, ensuring visual appeal and protection against external factors.

- Medical: PVC masterbatch is utilized in medical tubing, bags, and devices, providing biocompatibility and sterilization resistance.

- Consumer Goods: PVC masterbatch enhances the appearance and durability of various consumer goods, including toys, household items, and footwear.

Conclusion

PVC masterbatch unlocks a world of possibilities for manufacturers seeking to enhance the performance and visual appeal of PVC products. By understanding its benefits, formulation, and applications, manufacturers can harness the full potential of PVC masterbatch to create high-quality, durable, and sustainable products. With the right selection and utilization of PVC masterbatch, manufacturers can achieve superior color consistency, improved mechanical properties, UV resistance, flame retardancy, and more. Stay informed, collaborate with experts, and unleash the potential of PVC masterbatch in your next project.

Frequently Asked Questions (FAQs) about PVC Masterbatch

PVC masterbatch plays a crucial role in providing consistent and vibrant colors to PVC products. It ensures uniform dispersion of pigments throughout the material, resulting in visually appealing finished products.

Yes, PVC masterbatch can enhance the mechanical properties of PVC products, such as tensile strength, impact resistance, and flexibility. It strengthens the overall structure and durability of the final product.

PVC masterbatch can be formulated to be compatible with various PVC resins. Manufacturers can customize the masterbatch formulation to suit specific PVC resin types and achieve optimal performance.

PVC masterbatch incorporates UV stabilizers that prevent the degradation of PVC products caused by UV radiation. It helps maintain the color integrity and prolongs the lifespan of PVC materials.

PVC masterbatch can be formulated with environmentally friendly additives and pigments, making it a sustainable choice for PVC product manufacturers. It allows for the production of eco-friendly and recyclable PVC products.

Yes, PVC masterbatch can enhance the flame retardancy of PVC products by incorporating flame retardant additives. It helps reduce the flammability and improves the fire safety properties of PVC materials.

When selecting PVC masterbatch, factors such as the desired properties, compatibility with PVC resin, regulatory compliance, and application requirements should be taken into account. It is essential to work closely with a reputable supplier to choose the most suitable masterbatch for your needs.

PVC masterbatch can contribute to sustainable manufacturing practices by enabling the production of long-lasting, recyclable, and energy-efficient PVC products. It allows manufacturers to minimize waste, improve resource efficiency, and reduce environmental impact.

Yes, PVC masterbatch can be used in combination with other additives, such as impact modifiers, processing aids, or lubricants, to achieve specific performance requirements. It offers flexibility in tailoring the formulation to meet the desired product characteristics.

Yes, it is important to comply with relevant regulations and standards when using PVC masterbatch in different applications. It is recommended to consult with regulatory authorities or seek guidance from experts to ensure compliance with safety and environmental regulations.